Founded in 1975 by Giuseppe Manetti, now in its second generation, DUEMME is a joint-stock company operating in the field of non-destructive testing for third parties at the service of manufacturing companies operating nationally and internationally. Since 2009, the year in which it acquired its first linear accelerator, this historical excellence from Madignano (CR) has affirmed its leadership in its reference market, becoming a unique reality in its kind for the type of components tested and the quality of service provided, creating a significant technological and process gap with its direct competitors. Over time, the Manetti family has expanded the company’s core business to other strategic activities, diversifying its areas of interest by making significant investments to successfully enter other market segments.

by Roberta Imbimbo

Mr. Jacopo Manetti, what is the core business of the company founded by your father?

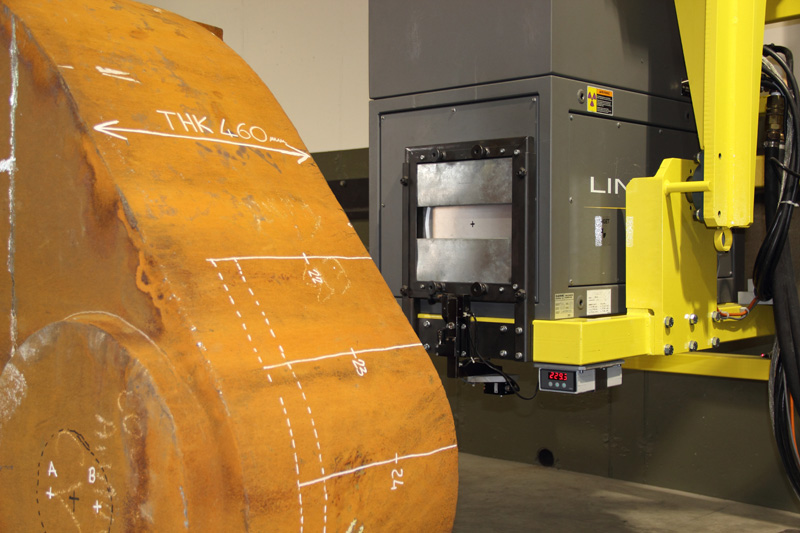

Founded back in 1975 as a company operating in the non-destructive testing sector for the inspection of methane pipelines and infrastructures, today DUEMME SPA is a company highly specialised in the execution of industrial radiographic and non-destructive testing in general, i.e. testing that allows an investigation of the component being inspected without damaging it. From its headquarters in Madignano (CR) – which covers an area of about 6,000 m2 where two different production sites and numerous bunkers owned and approved for performing radiographic examinations are located – it is able to operate throughout the national and international territory, in the Oil & Gas, Automotive, Aerospace, Medical, Electronics and Electrical Engineering, and Precision Mechanics sectors. The turning point came in 2009 with the purchase of the first linear energy accelerator, a latest-generation hardware factor that allows a broader spectrum of controls than the traditional method. The use of this state-of-the-art equipment has enabled the company to significantly increase its customer base, mostly manufacturing industries working with materials such as steel, cast iron, aluminium, light alloys and heavy alloys, whose products require surface or volumetric inspection.

What peculiarities distinguish us from our competitors?

Although it is a highly competitive market – in our country there are many companies operating in the field of non-destructive testing – DUEMME has managed to clearly differentiate itself from other players, thanks to the type of service provided, based precisely on the use of no less than three linear accelerators (3MeV, 6Mev and 9MeV) with a lifting capacity of 70 tonnes, capable of penetrating greater thicknesses of steel (up to 600 mm where traditional machines reach up to 100 mm) with the quality and definition required by the reference codes. More. In 2019, DUEMME has equipped itself with a tomographic system that, while operating at lower energies (up to a maximum of 450 KeV), is capable of carrying out non-destructive 3D volumetric inspection. With industrial computed tomography, DUEMME has therefore diversified its core business, increasing the range of services provided and investing in new infrastructures and new professionalism to successfully penetrate new market segments (every year, part of the profits made are reinvested in new technologies and staff training to keep the quality of the service offered high). The gamble made in 2009 to invest in innovative technology and the obtainment of important certifications, allow DUEMME to operate today, guaranteeing a quality service with a timeframe that is congruous with the requests of its clients, dealing with a high level clientele.

www.duemme.net